In the corn wet milling ethanol industry, you face unique challenges. Flowserve has spent decades creating unique offerings to help you get the most out of your ...

Traditionally, ethanol from corn has primarily been produced through dry and wetmilling processes. The majority of ethanol production is from drygrind technology.

Wet Milling of Cereal Grains ... were operating 14 wetmilling plants in 1950. ... modification of the corn wetmilling

is based in corn wetmilling plants. However, converting corn to ethanol through dry milling has the advantage of low capital costs ... Indiana Corn Dry Mill

REVIEW MILLING Wet Milling of CornA Review of LaboratoryScale and Pilot PlantScale Procedures N. SINGH'',2 and S. R. .

LBNL52307 Energy Efficiency Improvement and Cost Saving Opportunities for the Corn Wet Milling Industry An ENERGY STAR Guide for Energy and Plant Managers

Cargill Opens Iowa Corn Wet Mill Ethanol Facility. Cargill has begun operating its corn wet mill ethanol plant in Fort Dodge, Iowa. Cargill purchased the idled ...

Chemineer agitators and Kenics static mixers are utilized throughout the corn wet milling process.

PROCESS DESIGN FOR TREATMENT OF CORN WET MILLING WASTES ... plant of Corn Products Refining ... CPC International operates four wet milling plants in the ...

The Corn wet milling process is designed to extract the highest use and value from each component of the corn kernel. The process begins with the corn kernels being ...

corn wet milling plants in india – Grinding Mill China. New Enzymatic Corn Wet Milling Technology likely to be . Sep 25, 2010 · New Enzymatic Corn Wet Milling ...

Enzymatic corn wet milling ... A Technical Cost Model was developed for an enzymatic corn wet milling processing plant with a .

Use this tool to determine your wet corn milling plant''s ENERGY STAR 1 100 energy performance indicator score. The Energy Peformance Indicator (EPI) will help your ...

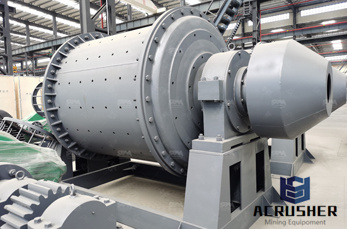

Corn Wet Milling Plant. We offer our client a precise quality range of corn wet milling plants. The machineries used in corn wet milling plant are robust in construction.

Incorporated in 1943, GPC was formed as an alcohol plant and has since grown to include maltodextrins, corn coproducts and a corn wet milling plant

Engineering process and cost model for a conventional corn wet milling facility ... new alkali process for extracting starch from corn. This plant

The corn wet mill ethanol plant will provide the base load corn grind for the campus, and will also support additional business growth in the coming years.

Cargill India, the Indian subsidiary of USbased food processing company Cargill, opened a new stateoftheart wet corn milling plant in...Read More...

Corn Wet Milled Feed ... Corn is the basic food plant of modern America and by far its most versatile grain. ... The Corn Wet Milling Process

Wetmilling is a process in which feed material is steeped in water, ... wetmilling plants can separate a 56pound bushel of corn into more than 31 pounds of ...

The purpose of this article is to examine the production of feed byproducts originating from wet and dry corn milling ... corn wet milling plant. ... wet corn gluten ...

The corn plant is a tall annual grass with a stout, ... Corn grain is processed by wet milling, in which the grain is soaked in a dilute solution of sulfurous acid; ...

Equipment and Systems for Corn Wet Milling. Corn Wet Milling Process Flowsheet 2. 3 Dewatering, Germ Washing, and Fiber Washing ... Most plants accomplish this very

Corn Wet Mill. The construction ... The plant?s primary product is fuel ethanol from Barley, a crop that can be grown in underutilized farmland of the region.

WhatsApp)

WhatsApp)